| Availability: | |

|---|---|

| Quantity: | |

| Specifications | WMD16 |

| Drilling Capacity | 16mm |

| End Mill Capacity | 16mm |

| Face Mill Capacity | 50mm |

| Spindle Taper | MT2 |

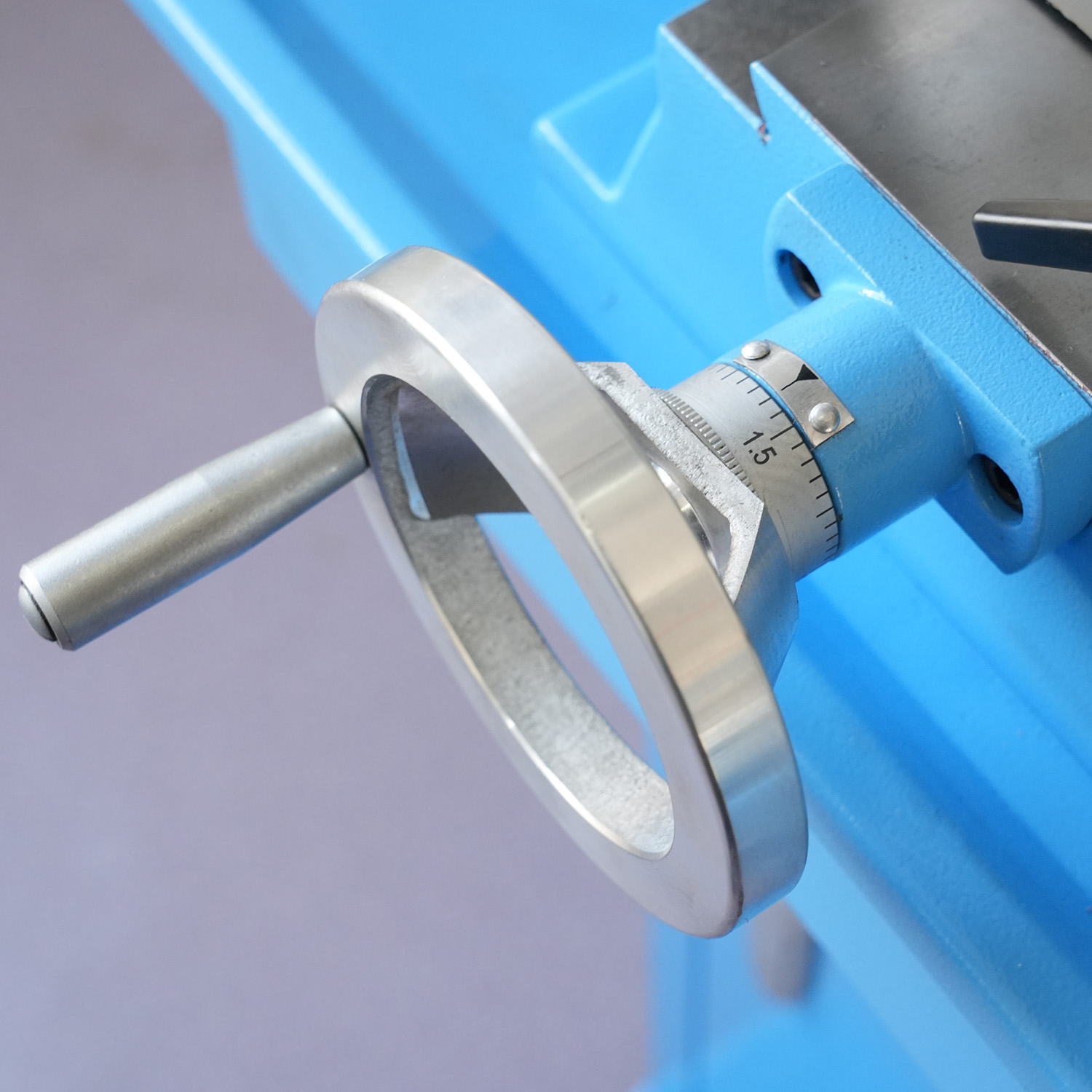

| Spindle Stroke | 50mm |

| Head Tilt | ±90° |

| Number of Spindle Speeds | Variable |

| Ranger of Spindle Speeds | 50-2250RPM |

| Working Surface of Table | 400*120mm |

| Max. Table longitudinal Travel | 220mm |

| Max. Table Cross Travel | 160mm |

| Max. vertical travel | 210mm |

| Number of T-Slots | 3 |

| T-Slot Size | 8mm |

| Motor | 500W,1Ph,230V |

| Overall Dimensions | 500*450*760mm |

| Net Weight(approx.) | 60KGS |

| Shipping Weight (approx.) | 70KGS |

|  |  |

|  |  |

Problem Solution | Possible Cause | Solution |

Too chatters | Gibs too loose on table, Unused feeds not locked Mill head not locked Quill too loose Tool not on center Improper tool shape, tool dull | Readjust gibs Lock all axes but the one moving Lock mill head Tighten quill lock Center tool reshape,sharpen, or replace tool |

Depth of cut is not consistent | Quill moving Setup wrong | Lock quill Make sure setup is parallel to table |

Hole is off center or bit wanders | Bit dull Bit not mounted correctly in chuck Chuck loose in spindle Drawbar not secured Bearing loosen or worn Cutting too fast | Use sharp bits Remount tool Remount chuck on arbor Tighten drawbar Tighten or replace bearings Reduce speed |

Bit turns erratically or stops | Bit fed into work too fast | Reduce feed rate |

Chuck is difficult to tighten or loosen | Chuck sticking Debris in chuck | Apply lubricant Clean chuck |

Chuck wobbles | Chuck loose on arbor Drawbar not tight | Clean arbor and remount Clean spindle and replace drawbar |

Turn on machine and nothing happer | Machine unplugged Loose electrical connections | Plug in machine Tighten wiring connections |